Advanced ZnO

From industrial waste to sustainable materials.

Catalyco produces high purity, high surface area zinc oxides for industrial applications in a circular way.

Based on 30 years of experience in producing high-purity, high-surface-area zinc oxides in a sustainable way.

Using our higher-performing zinc oxides, customers benefit by using less of these valuable resources, reducing manufacturing costs and reducing the environmental footprint of their products and business.

Industries

-

Chemical

Advanced Zno can help the chemical industry catalyzing cleaner processes to reduce CO2 emissions, aiding in efficient waste management, ensuring a resilient supply chain, and optimizing manufacturing costs through its multifunctional properties.

-

Rubber

Zinc oxide plays a pivotal role in the rubber industry by optimizing manufacturing processes, enhancing product quality, and addressing challenges such as rising CO2 footprint costs and supply chain vulnerabilities.

-

Tires

In the tire industry, challenges arise from legislation pushing for reduced use of virgin zinc oxide (ZnO) due to environmental concerns, as well as the toxicity of ZnO to aquatic life when released from tires. Innovative solutions are needed to maintain tire performance while minimizing ZnO usage and mitigating environmental impact.

-

Cosmetics

Zinc oxide serves as a crucial mineral ingredient in cosmetics, particularly in sunscreens, offering effective UV blocking properties. As a physical sunscreen agent, it creates a protective barrier on the skin’s surface, reflecting and scattering harmful UV rays to prevent sunburn and skin damage.

-

Ceramics

Our technology can lower melting points during firing, aids in particle fusion for denser ceramic bodies. It also acts as a glaze opacifier, enhancing opacity and brightness in ceramic glazes.

-

Glass

From a fining agent, to removing bubbles and impurities from molten glass to enhance clarity—zinc oxide can be used to impart specific properties such as UV absorption or conductivity to glass formulations.

Technology

We are enabling a circular economy and reuse of materials, resulting in reduced costs and a more secure supply of materials.

Our products embody unique features that greatly enhance performance and seamlessly integrate into traditional industrial processes.

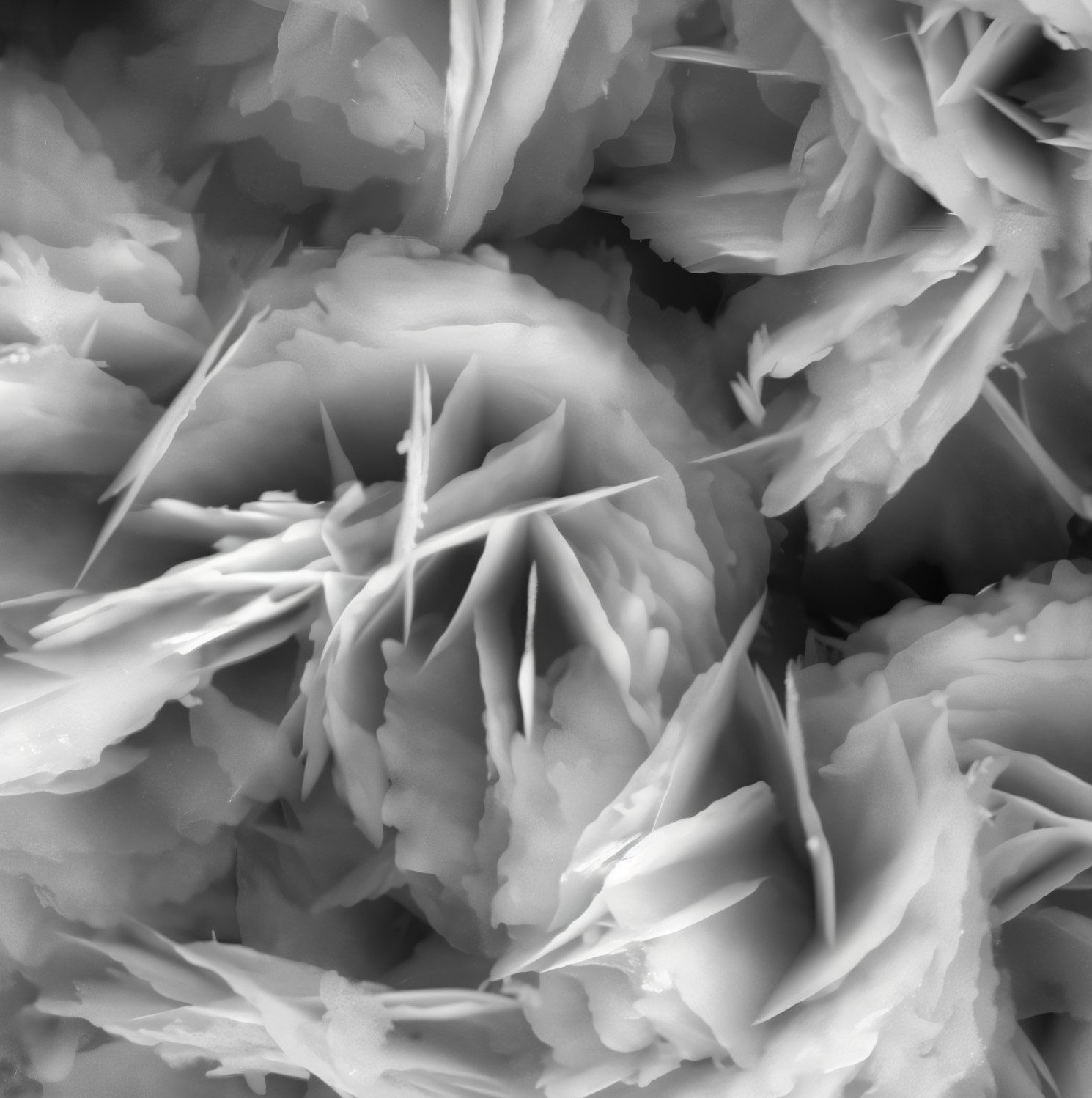

Extra high surface area ZnO, with unique structure and significantly reduced cadmium (Cd), copper (Cu), manganese (Mn) and sodium (Na) impurities.

Our method

Platform for material recovery.

Recovery process details.

-

Unlike pyro-metallurgical and hydro-metallurgical processes, our process is based on thermal multi-step precipitation.

-

More than 95%

-

High-Performance Zinc Oxide (high surface area above 50 m2/g)

-

Low energy consumption compared to conventional Pyro- and Hydro-metallurgical process

-

Lower temperature required - below 100 C and 400 C, or less than half than the temperature required for Pyro-metallurgical recovery

Impact

3 ways our solution contributes to a circular economy.

600,000+ m3

Water savings

Potential to reduce water use by 600,000+ cubic meters per year by switching to Catalyco’s ZnO (240 olympic-sized swimming pools)

1Mt CO2eq/year

Emission reduction

Potential to avoid up to 1 Mt of CO2eq per year.

230,000+ t

Waste reduction

Potential to avoid 230,000+ tonnes of waste (23 Eiffel Towers) annually.

Team

We are a team of keen deep-tech commercialization entrepreneurs and experienced scientists supported by an excellent advisory board with a lifetime of experience in the chemical industry and catalyst production.

Reinis Spunde

CEO / CO-Founder

MBA, entrepreneur with 25 years experience in sales and business development.

Vera Shchankina

CTO / CO-Founder

Co-founder, PhD, chemical research and IP security with 20 years experience. Author of IP.

Aija Hermane-Sabule

COO

MBA, Finances and management with 20 years experience. Has a podcast.

Baiba Medne

BDM

10 years of experience in project management and sales.

News

Stay up-to-date with news and announcements, from events to milestones.

Let’s Work Together

We’re always looking for new opportunities and are comfortable working internationally. Please get in touch and one of our project managers will contact you about beginning the proposal process.